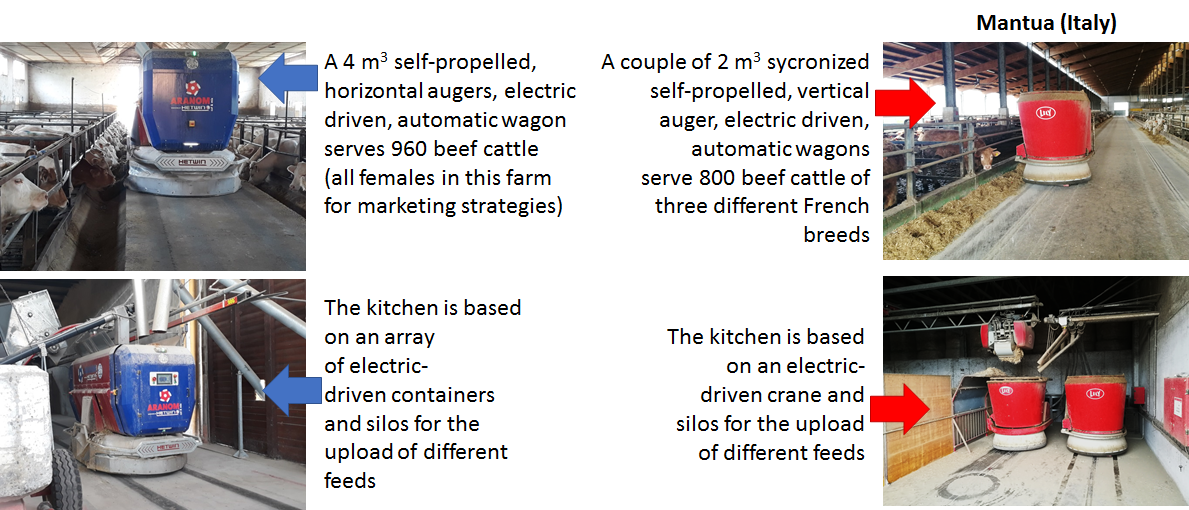

Labour shortage, the optimisation of energy use and the need for precision feeding to reduce feed waste are major challenges for beef cattle farms. The usage of automatic feeding systems (AFS) in cattle offers multiple advantages, primarily due to the possibility of an increased feeding frequency. The farm is equipped with a fully automatic feeding system (AFS). The beef cattle farm is specialized in the production of beef with different breeds of French origin.The AFS consists of two seld-propelled wagons that manage the ration of the groups independently. A fully automated kitchen fills the wagons with the ration to be offered to animals. The wagons operate 24 hours/day, and they can administer different rations to the various groups of animals (of different breed and age) according to their specific needs. After feed delivery, the way bulls access the feed indicates that all of the animals of the same pen have equal access to fresh feed. The system also monitors the animal performances and the herd's status and provides support in establishing animal health, body condition and growth performance.

There was the need to optimize the ordinary management of the farm focusing on the improvement of operators' efficiency, maintenance and running costs and precision feeding

The technology supplier has been contacted directly and soon after it the project started. After four months the automatic precision system was fully working.

The noise inside the barn dropped significantly. Now there is the chance to follow the animal's feeding behaviour throughout the year following the seasonality. The way animals receive the ration is always precise.

Many "small" issues arose (e.g., the feeding through distance, the slope in the floor, and its roughness) during the project's set-up: fixing them properly resulted in the full functioning of the AFS.

The details of the design of the barn, once fixed, allowed the machine to run at its best

Lessons learned of this research innovation are:

- The farmers have learnt to follow better the animal feeding behaviour and this way to optimize the technical efficiency

- The animal welfare is higher than before and this reflects on production quantity and quality

- The farmer has a great help in the ordinary management of the livestock unit and much less feed wastes

- An important improvement of the feed conversion rate can be obtained, as the AFS enables to provide precise quantities of feed for groups of animals that are differentiated according to breed and age.

Impacts are:

- Of course the investment in the AFS technology is relevant, but the economic benefits in terms of a higher feed efficiency, less energy use (no more diesel fuel to run the mixing wagon) and a lower labour input are significant

- Breeding animals in an improved housing environment equipped with AFS results in higher animal welfare and lower veterinary interventions compared to animals reared in other housings of the same company.

- A highly relevant benefit is that during the administering of the feed by the AFS much less noise is produced compared to tractor driven mixing wagon. Animals are therefore much less stressed

- A better feed efficiency has a postive impact on the carbon footprint of the farm.

Source: Operational Group AUTOFEED www.autofeed.crea.gov.it

Author: Kees de Roest - CRPA