The need to reduce labour and optimise the time spent on the daily handling of animals underscores the development of automated tools for use on cattle farms. An automatic cattle trough was developed to assist farmers in reducing labour and improving feeding efficiency by providing each animal with the amount and quality of feed consumed daily. The system has been installed on two dairy cattle farms, in Chylice and in Kociszew (Mazovia region) in Poland, showing very good results and improving production efficiency. The equipment was developed by the Institute of Animal Sciences at the Warsaw University of Life Sciences (SGGW) through the cooperation of researchers and farmers, and it is now ready for commercialisation on both dairy and beef farms.

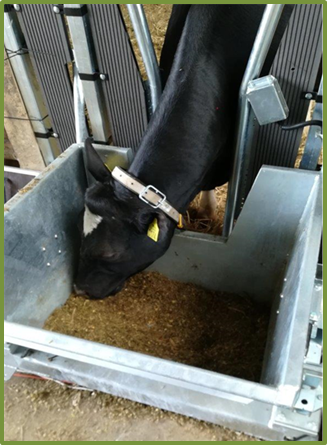

In this system, the animals are tagged with electronic Radio Frequency Identification (RFID) ear tags and are identified by an Information Technology (IT) system. The automatic cattle trough distributes the roughage precisely, according to the individual animal’s requirements. During a visit to the Smart Trough, each animal is recognised and registered by the RFID antenna and the process of weighing the feed begins. The amount of feed consumed by each animal during a fixed time is calculated by data obtained from the scales’ tensometric sensors, measuring the amount of feed at each visit. This entire process is monitored by the IT system.

The system can deliver additional information on the feeding behaviour of every single individual. In addition to feed intake, the following information can be obtained: animal ID, number of visits to stations, time spent at the station, effective feeding time, and time between visits.

In a traditional feeding system, where each component of the daily ration is delivered separately, the system can be programmed to be able to monitor the consumption pattern of every single type of feed. For instance, when some concentrate is added on top of maize silage and this information has been entered into the system, the Smart Trough can recognise that the animals will first consume the top ingredient of the ration, i.e. the concentrate, before starting to consume the other feeds below.

The installation of the equipment on the farm is very fast, taking only one day, and training the farmer takes about three days. The main challenge and bottleneck in the implementation process is the investment in IT infrastructure and the reorganisation of the feeding system.

This innovation is related to three BovINE themes: Socioeconomic Resilience by reducing feeding costs and Production Efficiency and Meat Quality and Environmental Sustainability by improving feed efficiency.

Source of information:

- Good practice provided by the Institute of Animal Sciences at the Warsaw University of Life Sciences)

Futher information:

- Innovation and Technology Transfer Centre at the Warsaw University of Life Sciences (SGGW): http://ciitt.sggw.pl/