Introduction

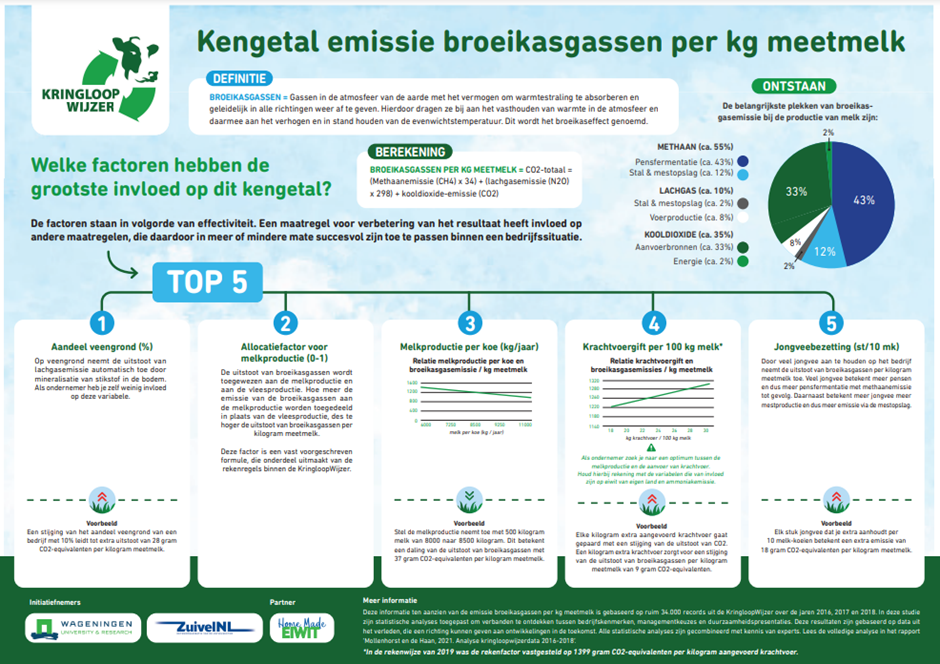

The KringloopWijzer is an instrument that shows dairy farms or farms with a dairy branch the cycle and the losses of nitrogen, phosphate and carbon. Use of the KringloopWijzer results in a number of key figures that farmers can use to justify their business operations to the authorities and processors, and on the basis of which they can also optimise their management. For the government in the Netherlands, the KringloopWijzer offers possibilities to partly replace generic legislation by custom-made solutions. For the processors of milk, for example, it also makes it possible to make the pursuit of sustainability measurable for the benefit of consumers.

Reason for the development and implementation of the Kringloopwijzer is that the dairy sector is keen to contribute to a better climate and environment by reducing the loss of minerals and the emission of greenhouse gases and ammonia into the soil, water and air.

In July 2013, the Dutch Dairy Organisation (NZO) and LTO Nederland presented the Dairy Plan 'Opportunities for the dairy chain after 2015'. One of the opportunities identified is the production of dairy products based on the efficient use of minerals on the dairy farm. Dairy farmers are an important link in this dairy chain. But how do you do that; produce milk in a sustainable way? The KringloopWijzer (the recycling guide) has been developed to show the efficient use of minerals and the emission of greenhouse gases and ammonia. This instrument shows you the mineral performance of the farm and gives you points of departure to improve it for your farm.

Description of the innovation

Beef | Parameters | Time needed | Complexity | Complete by | Cost |

✗ | Tier 2 |

|

| The farmer |

|

What makes this tool different in comparison with other tools?

It is not a complete C-footprint tool, but it is focused on the mineral fluxes of the farm. For this reason, all suppliers (dairy farms) of dairy companies affiliated with NZO (Dutch Dairy Organisation) are obliged to fill in the KringloopWijzer. This also applies to organic dairy farmers.

Enteric fermentation

For grazing animals other than dairy cattle, Tier 2 is used. The Tier2 calculation for methane emissions assumes that a fixed percentage of the gross energy absorbed is lost in the form of CH4. In the IPCC calculation rules this methane conversion factor YM for North West Europe is set at 6.5% for dairy cattle. This percentage is used here.

The calculation proceeds as follows. Without knowledge of the digestibility of feeds, the gross energy intake can best be estimated by multiplying the feed intake in kg dry matter (DM) by the average gross energy value of 18.45 MJ/kg DS. This conversion factor is relatively constant for different ruminant rations and is also recognised as a default value by the IPCC (IPCC, 2006).

Manure management

Cattle manure can be divided into thin 'farmyard manure', solid manure (i.e. farmyard manure in the narrower sense) and pasture manure. Thin manure is stored in the manure pit under the stables and in manure storage outside the stables. Solid manure is stored in the stable and in outdoor storage. In both cases, anaerobic conditions may occur resulting in the emission of CH4. This emission can be reduced by preventing anaerobic conditions, for example by aeration or regular conversion. However, the aerobic processes that occur do lead to higher emissions of ammonia and nitrous oxide. Of the total manure production in the Netherlands, the share of solid manure is relatively small.

Pasture manure is produced in the meadow during the grazing season in summer. Because of the mostly aerobic conditions, CH4 emission from pasture manure is usually relatively low. Besides the extent to which there are anaerobic conditions, the formation of CH4in the manure also depends on other conditions under which storage takes place, such as the amount of manure already present (so-called 'graft' or 'inoculum') and the storage duration and temperature. The manure cellar can be regarded as a so-called accumulation system: the 'reactor' (= manure cellar) is constantly being fed with manure and the volume of manure in the cellar increases until the cellar is emptied for fertilisation purposes or until the manure is pumped over to outside storage. The CH4 emission in such a system increases with the amount of (still) present manure (= inoculation), the manure temperature is higher and the duration of stay is longer.

The CH4emission from manure also depends on the (chemical) composition of the manure. For example, CH4emission is mainly dependent on the organic matter content of the manure.

In the KringloopWijzer it can be indicated how much slurry is being fermented externally and/or on the farm. In the KLW we assume that this manure has been in storage for less than 30 days before it enters the digester, so for this amount of manure an MCF (manure conversion factor) of 3 instead of 17 is used.

C sequestration

Crop residues and organic manure are the main sources of organic matter for the soil. soil. The supply via crop residues is calculated in the KringloopWijzer for grass and maize (maize for silage, MKS and CCM). For the supply via crop residues for crops other than those mentioned, crop-specific effective organic matter contributions from the literature have been used.

Impact on farm performance

Socio-economic resilience: In some cases, the Kringloopwijzer is obliged to fill in. All suppliers (dairy farms) of dairy companies affiliated to NZO are required to fill in the KringloopWijzer, also organic farms.

Animal health and welfare: AHW is not taken into account in this tool

Production efficiency and meat quality: PEMQ is not taken into account in this tool

Environmental sustainability: Explained above

Link to website (Dutch)

Link to website (Dutch)