https://ec.europa.eu/eip/agriculture/en/find-connect/projects/bovine-beef-innovation-network-europe

Excess of certain type of fat, such as intermuscular and subcutaneous, can reduce yield, while intramuscular fat my impact positively in the eating quality of beef. Marbling contributes to the economic value of carcasses and meat in some countries, where high scores is usually related to higher values. In Europe, the mandatory classification of carcasses implies conformation and fatness scores, but not marbling. In recent years, however, interest in marbling is growing.

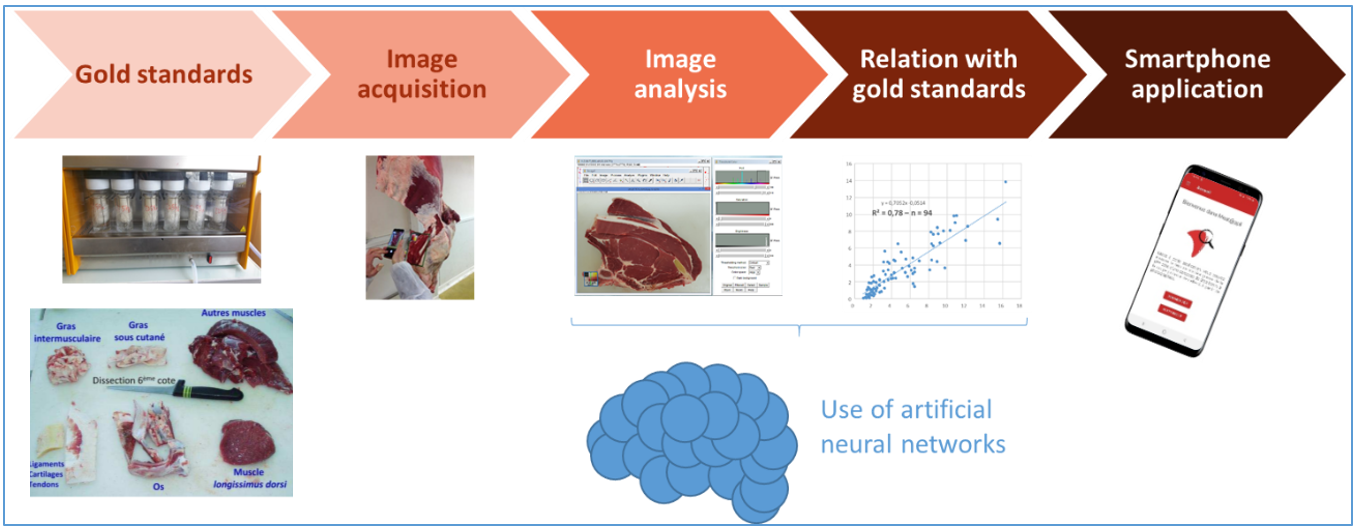

Thus, in the meat industry, a rapid, noninvasive and nondestructive evaluation and prediction of fat content in the cut is desired. The gold standard for marbling evaluation is the chemical analysis of intramuscular lipid content; while dissection is the gold standard to determine the percentage of fat in the rest of the adipose tissues (Figure 1). However, the major drawbacks of these gold standard methods are the destruction of the cut and the required the time and cost of the analyses. Therefore, alternative instrumental methods have been developed to predict beef fat content, such as the application of tomography, ultrasound and visible–near-infrared spectroscopy to carcasses or muscles/meat. But these methods are cost-effective and require sophisticated instruments. Several image analysis solutions have also been developed in several breeds with high potential. For example, a computer image analysis method based on a beef rib image was developed to determine the intramuscular, intermuscular and total fat content (Meunier et al., 2021; Kuchida et al., 2020; Jackman et al., 2009). These methods are generally less expensive but require time and expertise.

Figure 1: From a picture of the 6th rib of a beef carcass to the smartphone application Meat@ppli.

Figure 1: From a picture of the 6th rib of a beef carcass to the smartphone application Meat@ppli.

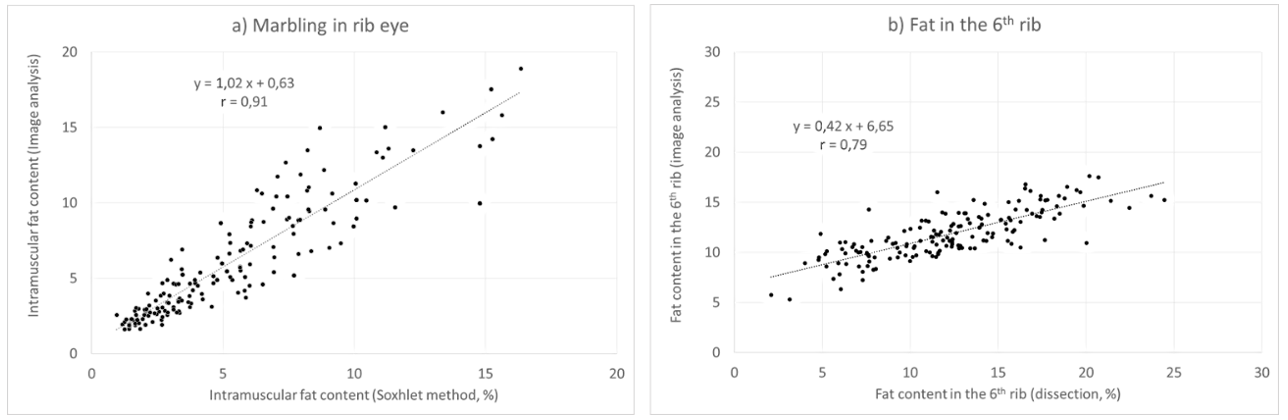

From 2017 to 2021, the Meat@ppli project aimed to develop an application for smartphones for fat measurement in a piece of meat at the carcass stage, in real time, in a reliable, economical and non-destructive way. The automatic image analysis algorithms were integrated into the Meat@ppli application which estimates in real time the fat content of the 6th rib of a beef carcass from its photo (Figure 1). As result, the correlation coefficients were 0.91 and 0.79, respectively, for the prediction of marbling and rib fat, in relation with the gold standards measurements (Figure 2).

Figure 2: Correlations between reference measurements and parameters from semi-automated image analysis, a) marbling in rib eye, b) fat in the 6th rib.

Figure 2: Correlations between reference measurements and parameters from semi-automated image analysis, a) marbling in rib eye, b) fat in the 6th rib.

A video, available on this link (https://vimeo.com/571657120), presents the smartphone application (in French).

However, the Meat@ppli application is still at the proof of concept stage and improvements are still possible. In the future, Meat@ppli could be used by the beef industry to route carcasses to the most suitable distribution channels and to perform massive phenotyping for the selection of bovines with appropriate marbling. Since the beginning of 2022, the French beef industry has developed a new marbling scale from 1 (no visual marbling) to 6 (large visual marbling), which will constitute a voluntary quality scheme. At the moment, it is a visual assessment, but Meat@ppli could allow an automated assessment in the future.

The next steps planned by IDELE are to continue with the development of Meat@ppli in order to measure more precisely the intramuscular fat content and reproduce the marbling grade according to the new scale. This application will help to improve the meat quality in France to respond better to consumer expectations.

Meat@ppli project was led by Jérôme Normand from IDELE (Institut de l'Elevage) in partnership with INRAE (Institut National de Recherche pour l'agriculture, l'alimentation et l'environnement) and Pascal Institute (joint research unit of Clermont Auvergne University, CNRS and Clermont Auvergne INP).

Authors:

- Jérôme Normand – Institut de l’Elevage, Carcass and Meat Quality Department – Lyon, France – jerome.normand@idele.fr

- Christophe Denoyelle – Institut de l’Elevage, Carcass and Meat Quality Department – Paris, France – christophe.denoyelle@idele.fr

- Reviewed/edited by Jakeline Viera Romero and Virginia Resconi, Universidad de Zaragoza (Spain).

Impact on:

|

The cost-effectiveness of the application is still unclear. It could allow a payment based on quality. |

|

|

|

It will allow to classify carcasses according to commercial interest. The application can phenotype several carcasses useful for future animal selection to improve yield and meat quality. It can also help to improve quality by on-farm strategies. |

|

it may help to reduce trimmable fat and consequently reducing environmental impact. |

Source of information:

- Bonnet et al., 2020. EAAP, 71st Annual Meeting, Session 43. From an open-access computer image analysis method to a smartphone app for beef marbling evaluation.

- Meunier et al., 2021. An open-access computer image analysis (CIA) method to predict meat and fat content from an android smartphone-derived picture of the bovine 5th-6th rib. Methods, 186:79-89.

- Normand et al., 2022. Meat@ppli - application smartphone pour déterminer la teneur en gras de la viande bovine en temps réel. Innovations Agronomiques, 85 :213-223. https://www6.inrae.fr/ciag/content/download/6993/50293/version/1/file/16-Normand+et+al.pdf

- Kuchida et al., 2020. Prediction of crude fat content of longissimus muscle of beef using the ratio of fat area calculated from computer image analysis: comparison of regression equations for prediction using different input devices at different stations. Journal of Animal Science, 78:799-803.

- Jackman et al., 2009. Automatic segmentation of beef longissimus dorsi muscle and marbling by an adaptable algorithm. Meat Science, 83:187-194.

Further information:

Web site: https://idele.fr/meatappli/