Introduction to the challenge addressed

In 2004, following agreement among the various beef stakeholders, Ireland changed from manual beef carcase classification to mechanical carcase classification, introducing video imaging analysis (VIA) technology in most meat plants to measure conformation and fat score. For consistency, it was agreed to install a similar system in all participating meat plants called the VBS 2000 supplied by e+v.

Prior to this, farmers were critical of the manual classification system, mainly because it depended on human judgement and was considered to be subjective and inconsistent. In addition, this lack of confidence prevented the introduction of quality-based payments schemes that reflected the true value of the carcase.

It was considered mechanical classification would be objective and consistent and deliver results that were at least as good as manual classification.

Description of the Good Practice

In the EU, beef carcases are classified according to the official EU scheme (EC 1208/1981) for conformation (E, U, R, O, P) and fat cover (1-5).

Traditionally and in most EU countries, carcase classification is carried out manually, where a licenced grader undertakes a visual assessment of the carcase and then proceeds to give it a classification score for conformation and fat based on the EUROP grid. The objective of the EU classification system is to ensure a common system and standard of classification across EU countries which in turn facilitates a standardised price reporting system.

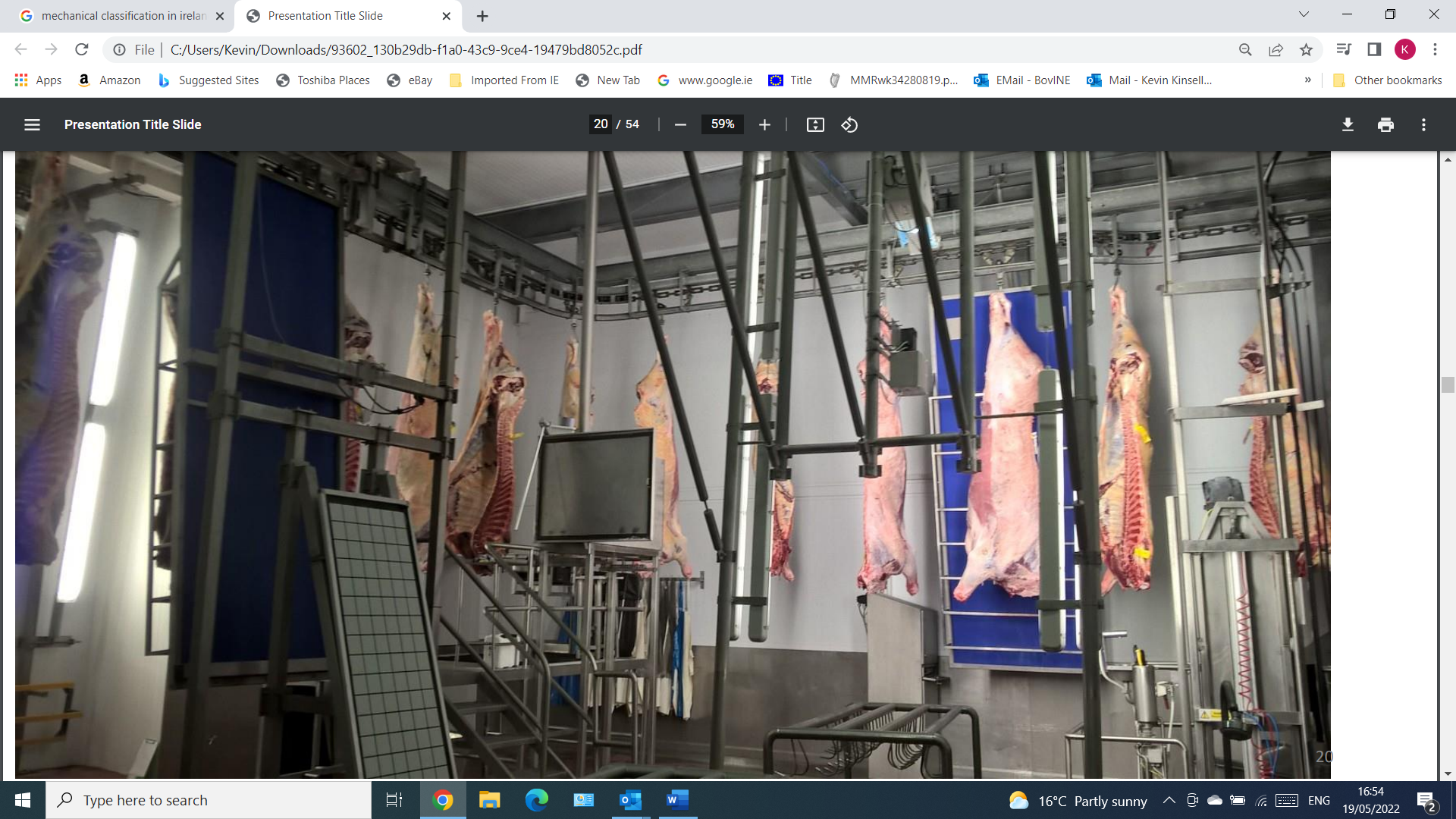

With mechanical classification, the human grader is replaced on the slaughter line with a machine that uses video cameras and computer software to classify the carcase. With VIA, a half carcase is suspended against a purpose-built backdrop and illuminated with specialist LED lights. Digital cameras take a series of pictures of the carcase side. The contours and other measurements of the carcase are analyses to access conformation and carcase colour is compared to access fat. The data is then analysed and processed by the software to produce both a conformation and fat score for the carcase.

The VIA technology can provide a breakdown of the conformation and fat from a 5-point scale (EUROP and 1-5) to a much more detailed 15-point scale e.g. U-3+, O+2=.

VIA technology can also be to calculate the meat yield of the carcase and while some meat plants use this technology, it has not been introduced at farm level for payment purposes.

Ongoing checks and inspections are carried out by the component authority (Department of Agriculture) to ensure that the mechanical classification machines are working correctly and in line with the requirements laid down by the EU regulations.

Picture of Mechanically Classification VIA technology in operation in a meat plant

In 2009, based on scientific research by Teagasc, the Irish beef sector introduced a Quality Payment System (QPS) to pay for cattle, which was possible through the utilisation of the 15-point scale classification system based on mechanical classification. The QPS was a move away from flat pricing to a payment system based on price differentials, scientifically determined around meat yield value, geared at rewarding the farmer based on market specifications and requirements.

Quality Payment System (QPS)

c/kg | U+ | U= | U- | R+ | R= | R- | 0+ | O= | O- | P+ |

2+ | 24 | 18 | 12 | 6 | 0 | 0 | -18 | -24 | -30 | -36 |

3 | 24 | 18 | 12 | 6 | 0 | 0 | -12 | -18 | -24 | -30 |

4- | 24 | 18 | 12 | 6 | 0 | 0 | -12 | -18 | -24 | -30 |

4= | 24 | 18 | 12 | 6 | 0 | 0 | -12 | -24 | -30 | -36 |

4+ | 18 | 12 | 6 | 0 | -6 | -6 | -18 | -24 | -30 | -36 |

5 | 0 | -6 | -12 | -18 | -24 | -24 | -36 | -42 | -48 | -54 |

Additional in-spec bonuses paid for animals that meet certain criteria (age, quality assurance, residency on final farm, movements) in the shaded areas.

Impact of farm performance

The introduction of mechanical classification and subsequently a payment system based on quality was a significant move and helped the economic returns and sustainability of quality suckler based beef production. It also focused the beef sector on the need to breed quality beef animals and rewarded producers for meeting market specifications.

Audio-visual material

Farmer comment

“As a beef finisher that regularly sells animals to a meat plant using mechanically classification, I find the system more accurate and especially more consistent than the old system of manual classification. In addition, as a suckler farmer breeding quality animals, I believe the quality payment system, based on the 15-point scale better reflects and rewards me for the true value of my animals.”

Further information

https://www.gov.ie/en/collection/bc95b-eu-beef-carcase-classification-scheme/#reports

https://www.teagasc.ie/media/website/publications/2000/beefgrading.pdf