Introduction to the challenge addressed

Introduction to the challenge addressed

In Estonia, there is a grass-fed beef quality scheme currently involving 112 farms as members, with mostly Aberdeen Angus and Hereford breeds, where cattle are usually finished grazing pastures named: Liivimaa Lihaveis.

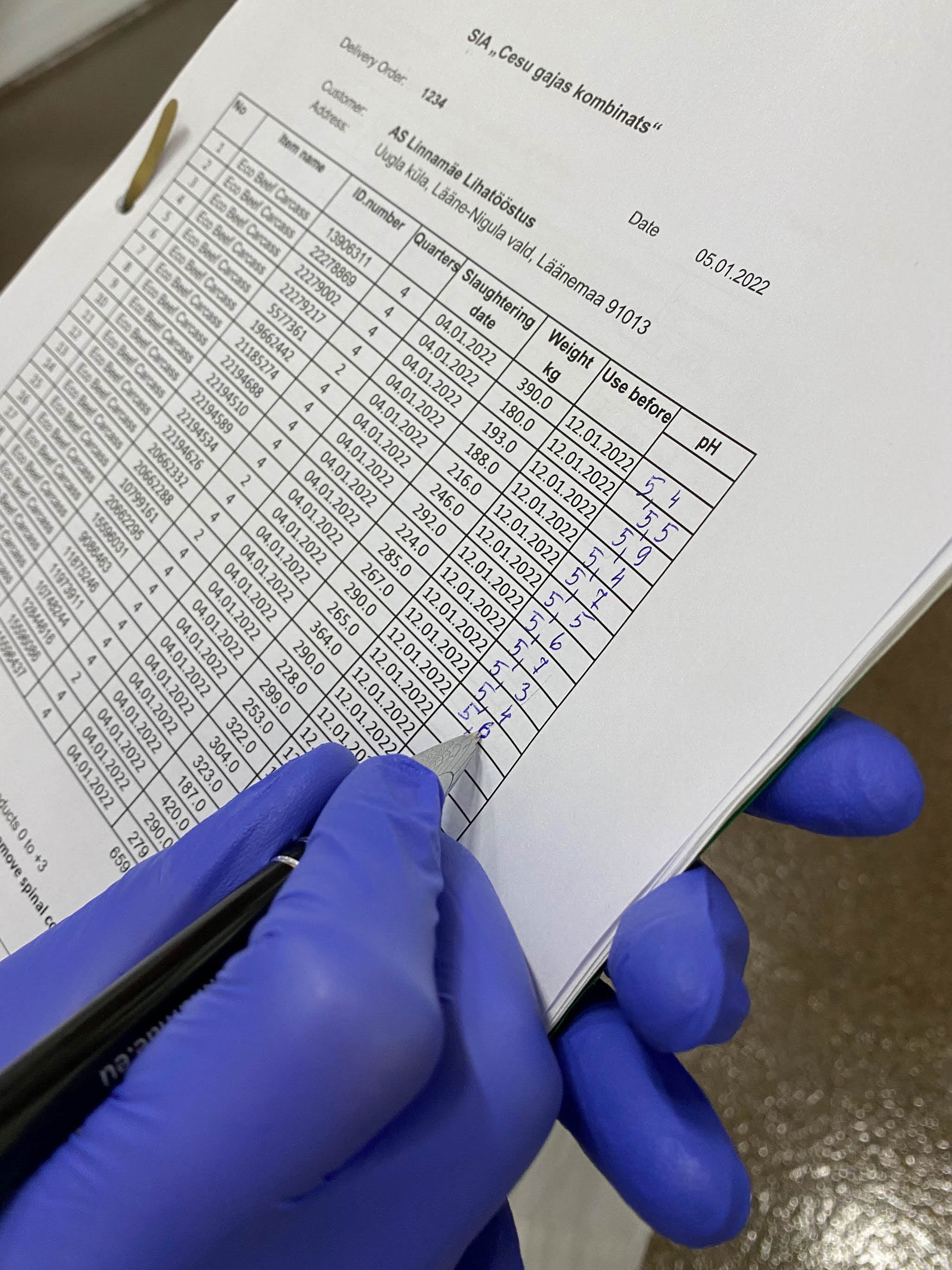

To prevent that the meat of well reared cattle is not spoiled during pre-slaughter stress producing by high meat pH, a data monitoring of carcass pH was performed to identify risk factors and try to reduce them. High pH meat cannot be sold as quality meat and the ecological footprint of beef depends on every kilogram wasted, therefore, it was decided to tackle this problem by this non-profit organization.

Description of Innovation

During the three-year period 2018-2020, the pH from all the carcasses under the Liivimaa Lihaveis beef cattle quality scheme brought to the slaughterhouse was measured. The total amount of the carcasses evaluated was 3,925. In 2018, they were 1,249 carcasses, in 2019: 1,022 carcasses, and in 2020: 1,645 carcasses; coming from 58, 73 and 52 beef farmers, respectively.

The pH was measured 48 h after slaughter, just before loading and transporting carcasses to the cutting plant. If the pH of some carcasses was above 5.7, three stakeholders directly involved in the pre-slaughter management of the animals were interviewed by Airi Külvet, the board member of Liivimaa Lihaveis. The questions were:

- To the farmer. How was the concentration of animals on the farm carried out? Was there any avoidance of grouping animals from different herds of the owner? On a scale of 1 to 5, how did the owner rate the driver or his own animals being driven onto the truck?

- To the driver. Were there any problems on the farm? How were the animals loaded, how many minutes did it take? How was the journey, were there any unforeseen incidents, did the barriers hold up? How did the animals behave when unloaded at the slaughterhouse? What was the temperature? Were the animals unloaded from the truck immediately or did the truck have to queue?

- To the slaughterhouse staff was interviewed about how the animals were moved to the slaughterhouse, whether there were problems with stunning.

Impact on farm performance

As a result of this work, we generally got a very good picture of what is most likely to cause the animals' pH to rise and meat quality to deteriorate. Along these years, the most important factor was that the animals were stressed already on the farm, since there were several different herds being put together before loading. Fewer were the cases where there were problems on the way, the partition broke open, animals from different farms got mixed up. There were cases where the driver had to stand for hours at the gate of the slaughterhouse and could not unload the animals (this is a risk factor). Very rarely there were cases where everything was fine before but there was a problem with the slaughter box and an electric pick was used. As a result of this work we did a workshop where we brought farmers and drivers to prevent incidents. Immediate feedback was given to the farmers personally on a case by case basis.

As a result, the pH problems were reduced to the extent that we no longer measure 100% but do spot check to the domestic market. It is still measured 100% of the carcasses that goes to the export market (around 50 % of annual carcasses are destined for export markets).

From the carcasses checked during 2018 -2020, the results where:

• 2018 – 1.6% animals with high carcass pH

• 2019 – 3.0 % animals with high carcass pH

• 2020 – 0.9 % animals with high carcass pH

The main values where also direct, by the day-to-day contact with people.

Image Caption

Image CaptionFarmer comment (for Good Practices)

„The understanding of animal welfare is different. Drivers changed, the welfare training that was nationally required did not serve its purpose at all, a lot of the information we provided came as a surprise to drivers. Raising awareness of stress and animal behaviour among livestock owners and other people involved was importnant result of this good practices.“

Liisi Laos, Kirbla Mahe, member of MTÜ Liivimaa Lihaveis